Novocoppo Mediterraneo, Torrita di Siena (SI)

Luogo: Torrita di Siena (SI) Materiali utilizzati per la copertura: NOVOCOPPO colore MEDITERRANEO Foto: 14 luglio 2022 archivio Terreal Italia Srl

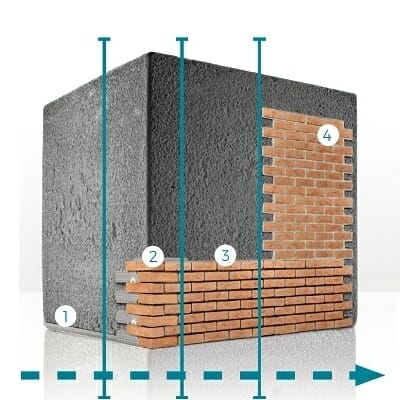

TERRACOAT® is an efficient cladding system for the thermal insulating of buildings, consisting in prefabricated panels forms by assembling EPS sheeting with added graffite and exposed terracotta slats with a thickness of 2 centimetres.

The characteristic assembly system ensures that the two components are firmly glued together, to create a singular and indivisible body with a very high resistance to atmospheric agents.

Prefabrication is carried out at the Terreal Italia establishment under controlled conditions using standardised procedures.

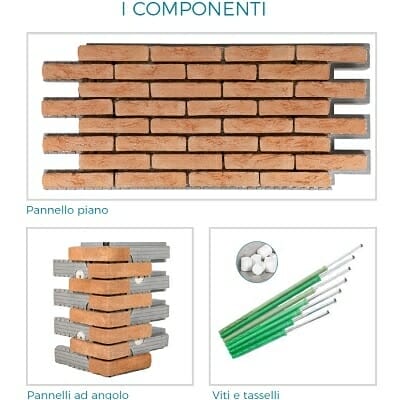

The small size, equivalent to 0.54 square metres per panel and the limited weight (approximately 17.4 kilograms) render the panel very versatile in terms of logistics and worksite storage whilst ensuring swift and simple installation.

The panels are mechanically secured to any support structure – be it a wooden wall or the more traditional hollow-core concrete wall, or even the reinforced concrete panels of prefabricated structures.

The TERRACOAT® system ensures high thermal performance of the building whilst improving aesthetics thanks to the soft-sludge exposed terracotta slats in the variety of finishes and colours of the SanMarco and Pica range.

Such characteristics mean TERRACOAT® is perfect for building renovations and redevelopments as well as in new constructions.

Amongst the advantages is undoubtedly the extensive durability and the absence of maintenance, as well as the simplicity of installation.

1. Secure the starting profile to be level along the entire base of the construction (off the ground, as per the project) and evenly distribute two polyurethane foam extents along the entire starting profile.

2. After applying polyurethane foam on the rear of the panel (with the frame method and vertical central bands) begin the sequence of laying from the corner (if foreseen) then proceeding with the panels from left to right and bottom to top.

3. After drilling the support wall in line with the anchor bolt washers present, insert the screws with dowels then screw in. It is recommended to cover the heads of the screws with the EPS cylinders included in the kit by pushing them in until the head of the screw to eliminate any thermal bridges.

4. Once the entire wall is covered (after at least 24 hours), it is possible to proceed with grouting the horizontal and vertical joints by applying the FM 50 TC mortar and finishing off with styling and deburring as per the project.

THE TERRACOAT® PANELS ARE MADE OF:

• the side “comb” with rounded ends;

• the closing/conical overlap of the lateral edging.

These aspects set TERRACOAT® apart both aesthetically and technically, offering better fastening and thermal insulation along the edges whilst ensuring a superior seal against air and water.

Luogo: Torrita di Siena (SI) Materiali utilizzati per la copertura: NOVOCOPPO colore MEDITERRANEO Foto: 14 luglio 2022 archivio Terreal Italia Srl

Miscelazione Giallo 80% / Rosato 20% di mattone Sabbiato Pica, produzione Castiglion Fiorentino. Cantiere Montecosaro Scalo (MC) via F.lli Cervi.

Novocoppo Mediterraneo Pica. Azienda Agricola Agritoppi – Lucera (FG)

By clicking on “subscribe” you accept to receive our newsletter. You can always unsubscribe through the link “unsubscribe” that is present in every email that you will receive. For further information, please read our policy.